The spindle is one the most crucial components in modern manufacturing where accuracy and reliability can’t be compromised. The spindle is accountable for speed, precision and consistency, whether you’re machining high-grade aerospace alloys or fine tuning parts that require extremely tight tolerances.

The top of this industry are the top spindle manufacturers such as POSA Machinery, who are redefining what the performance and durability of their products look like in industrial machining environments.

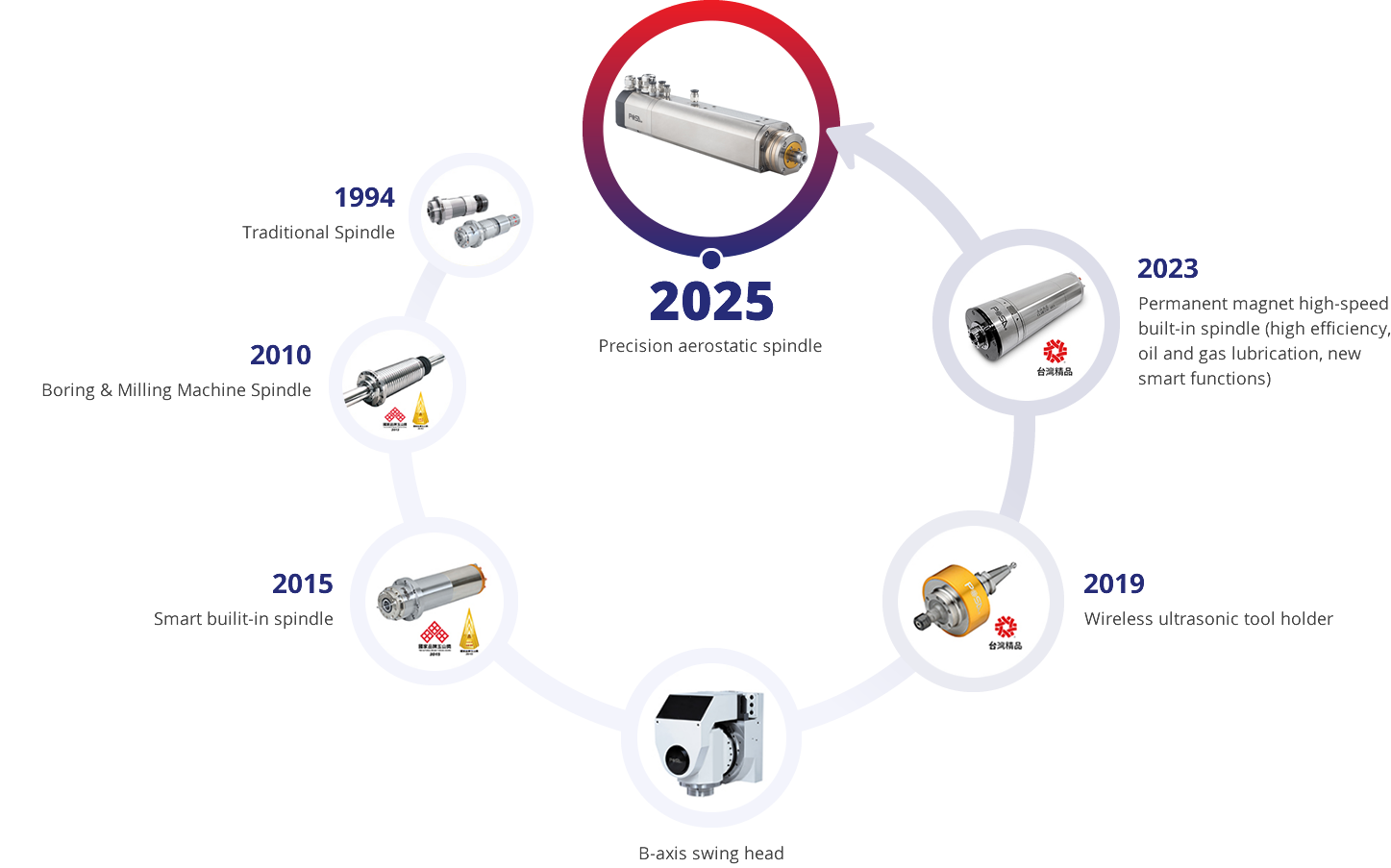

Image credit: posa-spindle.com

The reason the Spindle Is the Heart of the Machine

The spindle’s quality is the most important element in every CNC machine. Consider the spindle as the core of a CNC lathe or machining center. it is the engine that drives the cutting tool with astonishing precision as well as stability and torque. Spindles that aren’t aligned correctly or constructed poorly can result in malfunctioning parts, damage to the machine and diminish the life of the tool. They can also disrupt the manufacturing process.

This is where precision spindle technology is what makes the difference. Precision spindles are not mass-produced parts that can be assembled quickly. They are designed carefully by calibrating, testing, and testing to perform under extreme conditions.

POSA: More Than a Spindle Manufacture

POSA Machine is a pioneer in spindle production for years. While many spindle manufacturers claim to be high-precision however they are not equipped with the knowledge and expertise in engineering that POSA has gained over those years. Spindles made by POSA are famous for their rigorous in-house quality standards and rigorous testing procedures. They also create solutions that perform that meet the different demands of today’s industry.

POSA spindles can be found in a myriad of machines, from horizontal and vertical machining centers to tool grinding machines. Every spindle is backed by an extensive R&D process that is not just on functionality but also on long-term reliability, vibration control, and thermal stability.

The Evolution of the CNC Lathe Spindle

The CNC lathe spindle has seen remarkable innovation in recent years. Not just a rotational axis; today’s spindles are incorporating sensors, cooling systems, and intelligent balancing mechanisms. POSA’s CNC lathe spindles are a perfect example that combine high-speed capabilities along with exceptional torque and rigidity, offering machinists the flexibility to work with delicate materials as well as hard metals with no compromise on quality. These spindles, made from high-quality steel as well as advanced ceramic bearings, limit the expansion of thermal energy while maintaining precise tolerances throughout long runs. This dependable design results in better part quality and reduced downtime.

Tailored Machining Spindles for Real-World Needs

There’s no standard size that can be used for spindle for machining, especially in areas such as die and mold manufacturing or aerospace, automotive. POSA knows that every application has specific requirements. Whether it is spindle speed or load capacity or environmental resistance, POSA can meet them. This is why POSA provides customized spindle designs based on the requirements of each customer. Whether it’s designing a spindle for vertical milling or integrating a high-frequency spindle into a compact system, POSA provides the flexibility and engineering support that modern manufacturers need.

More than just machinery A commitment to the art of crafting

What is what sets POSA apart isn’t its collection of spindles, it’s the philosophy behind them. The company believes in the fusion of innovation and craftsmanship. Their design engineers work closely with clients take note of their pain points and continually adapt their offerings to stay ahead of market trends and demands. In a world where machine uptime as well as repeatability are the most important factors to a production line’s success choosing the most suitable spindle partners is essential.

Final Thoughts

The future of manufacturing isn’t just about higher-speed machines. It is also about more intelligent and more reliable parts. POSA Machine is a fantastic example of what spindle makers can accomplish when they combine their technical expertise and a customer-first mindset. Select the best spindle for your needs, whether you’re seeking a top-quality CNC spindle, or a heavy duty machining spindle.